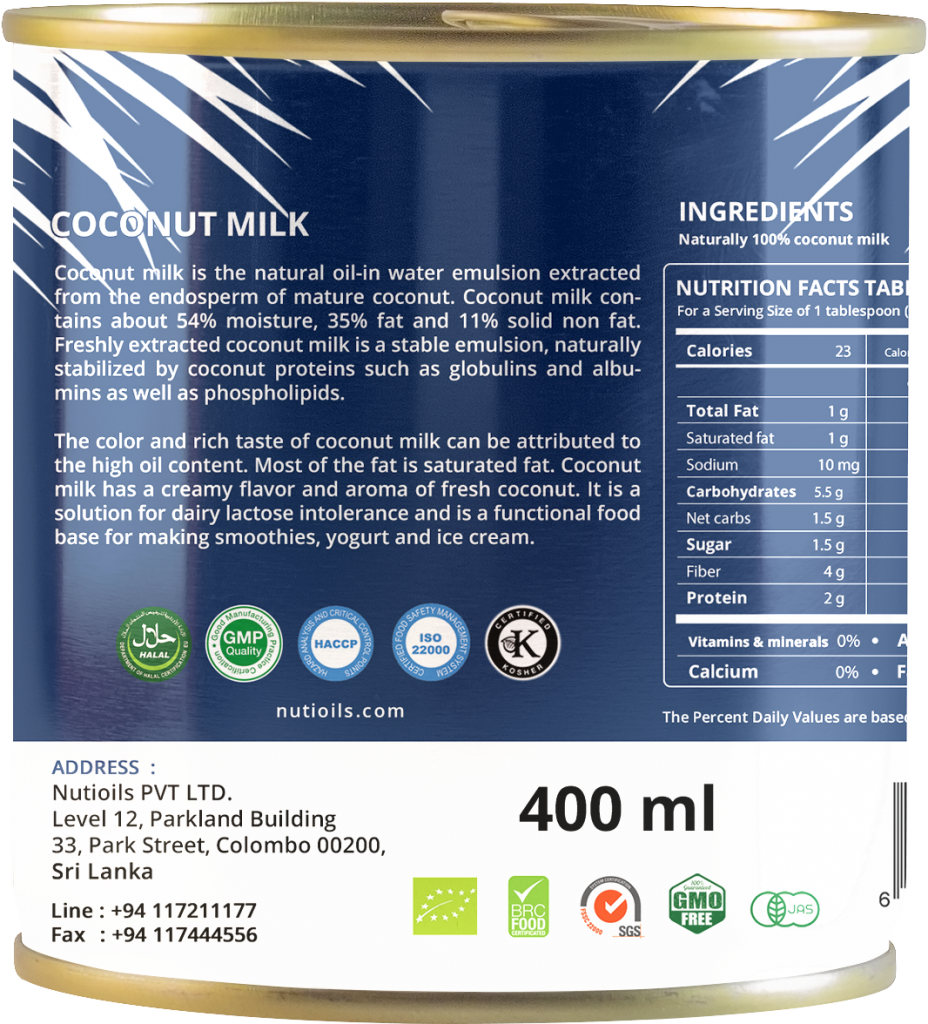

Coconut milk is the natural oil-in water emulsion extracted from the endosperm of mature coconut. Coconut milk contains about 54% moisture, 35% fat and 11% solid non fat. Freshly extracted coconut milk is a stable emulsion, naturally stabilized by coconut proteins such as globulins and albumins as well as phospholipids..

+94766049617

Nutritional Composition

SERVINGS : 1TSP (8.51 g)

| Calories from Fat 9 (39.1%) | % Daily Value * |

| Total Fat 1g | - |

| Saturated fat 1g | - |

| Sodium 10mg | 1% |

| Carbohydrates 5.5g | - |

| Net carbs 1.5g | - |

| Sugar 1.5g | - |

| Fiber 4g | 16% |

| Protein 2g | Vitamins and minerals |

| Calcium 0mg | 0% |

| Fatty acids | Amino acids |

The color and rich taste of coconut milk can be attributed to the high oil content. Most of the fat is saturated fat. Coconut milk has a creamy flavor and aroma of fresh coconut. It is a solution for dairy lactose intolerance and is a functional food base for making smoothies, yogurt and ice cream Some of the proteins present in the aqueous phase of the coconut milk interact with fat globules and act as emulsifier by surrounding its surface.

Some of the proteins present in the aqueous phase of the coconut milk interact with fat globules and act as emulsifier by surrounding its surface. Improved stability of coconut milk emulsions homogenized is achieved with various surface-active stabilizers, i.e., 1% weight sodium caseinate, whey protein isolate (WPI), sodium dodecyl sulfate (SDS), or polyoxyethylene sorbitan monolaurate.

Freshly prepared coconut milk emulsions (1.8–2% protein, 17–18% fat) have large (d43∼10 μm) but non-flocculated droplets. Homogenization reduced the primary droplet size but induces flocculation.

Adding small-molecule surfactants after the homogenization step can displace coconut proteins from the interface and break up these flocs, but adding them before homogenization increases the efficiency of the homogenization step and produces stable, submicron-sized emulsion droplets. Adding protein stabilizers does not break up the flocs of coconut milk droplets when added after homogenization, but does increase the efficacy of the homogenization step when added prior to it.

Adding stabilizers to non-homogenized coconut milk has no effect on the structure or properties of the emulsions.Homogenized coconut milk prepared without additives may be destabilized by freeze–thaw, (200C and 10 0C) but not by chilling (50C).

Homogenized coconut milk with proteins is not affected by low temperature treatments while those prepared with surfactants are stable to chilling but partially or fully coalesced following freeze–thaw. Homogenized coconut milk prepared without additives will coalesce and flocculate after being heated at 900C or 1200C for 1 h in due to the denaturation and subsequent aggregation of coconut proteins. Coconut Milk emulsified with caseinate will not be affected by heat treatments while those prepared with WPI will show extensive coalescence and phase separation after being treated at 900C or 1200C.

Coconut Milk prepared with SDS will be table to heating but Coconut Milk prepared with Tween 20 will be completely destabilized by heating at 1200C. The homogenized coconut milk is unstable itself and its stability is decreased either after freeze–thaw or after heating to temperatures sufficient to denature the coconut proteins. The samples emulsified with proteins are stable to low temperature treatments but only with caseinate is Coconut Milk stable against heating.The selection of surface-active stabilizer is important in producing coconut milk products that are able to maintain good stability and quality after being treated under processing conditions.

+94766049617